Overview

When setting up a new product, there is an option to select 'Catch Weight'. Catch Weight is for products ordered by quantity but received and invoiced by weight. An example of this would be a whole salmon, as the user would order one salmon, but the weight of the fish can vary massively, so the supplier invoices by weight.

While the principle is simple, it can be confusing setting up a product correctly for catch weight as well as understanding how to make the order. This article shows the process for both, from creating the product, to receiving the Purchase Order.

Setting up a Catch Weight Product

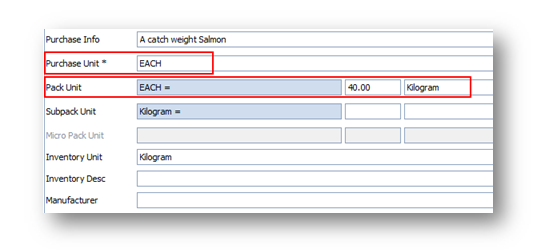

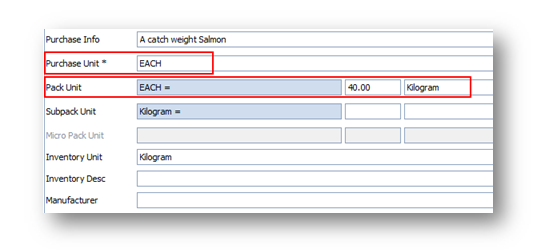

When building a product that is catch weight the purchase unit is defined by the applicable quantity name (each, case, piece, etc). That unit is then defined into further pieces or weight. The average weight of the item is input so the system has a baseline to calculate what the received weight will be, however actual weight will be updated at the time of receiving.

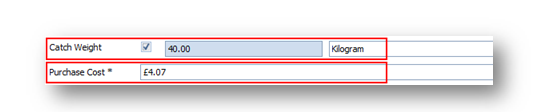

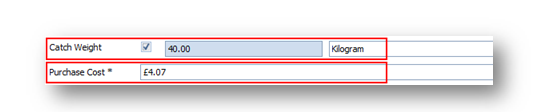

An example of this is shown in Fig.1, which shows that the user buys a Salmon as EACH, where ‘EACH’ salmon will be 40 kilograms. The Catch Weight option is checked and also set to 40 kilograms. The Purchase Cost is the price per kilogram, for example, if the user buys a salmon that is exactly 40 kilograms, the total cost will be 40 x £4.07 = £162.80.

Creating a Purchase Order

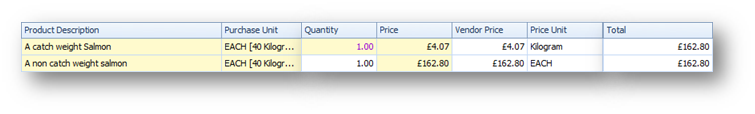

Fig.2 shows a Purchase Order with both a catch weight salmon and a non-catch weight salmon. In both instances, an order is placed in ‘Quantity’, where the user is purchasing one product each where each is 40 kilograms. The price for the catch weight product is shown as cost per kilogram, whilst the non-catch weight product is the cost of each.

Please note: When ordering a catch weight item, the quantity figure will display as purple to signify that the product is a catch weight item.

Posting at Receiving

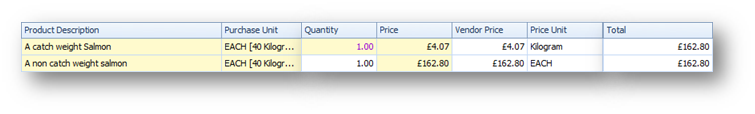

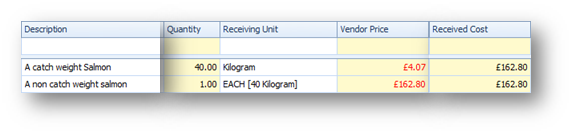

The difference between the two products is shown at the Receiving Center. The catch weight product has the ‘Receiving Unit’ in weight, whilst the non-catch weight item is as ‘EACH’, as shown in Fig.3.

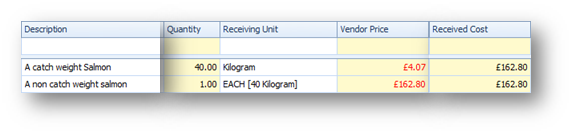

The advantage of catch weight can be seen in Fig.4. It is simple for the user to amend the catch weight salmon to the correct weight – which in turn will correct the ‘Received Cost’.

Correcting the non-catch weight salmon would mean the user would have to determine the new weight as a percentage of the original weight. This method is more time consuming, prone to errors, and less accurate as the ‘Quantity’ is limited to 2 decimal places.

When setting up a new product, there is an option to select 'Catch Weight'. Catch Weight is for products ordered by quantity but received and invoiced by weight. An example of this would be a whole salmon, as the user would order one salmon, but the weight of the fish can vary massively, so the supplier invoices by weight.

While the principle is simple, it can be confusing setting up a product correctly for catch weight as well as understanding how to make the order. This article shows the process for both, from creating the product, to receiving the Purchase Order.

Setting up a Catch Weight Product

When building a product that is catch weight the purchase unit is defined by the applicable quantity name (each, case, piece, etc). That unit is then defined into further pieces or weight. The average weight of the item is input so the system has a baseline to calculate what the received weight will be, however actual weight will be updated at the time of receiving.

- To set up a catch weight product, enter EACH into the Purchase Unit* field, and then enter the weight of the object in the Pack Unit field

- The Catch Weight option must also be checked and set to the weight unit which the vendor prices the item

- Enter the price per kilogram into the Purchase Cost field.

An example of this is shown in Fig.1, which shows that the user buys a Salmon as EACH, where ‘EACH’ salmon will be 40 kilograms. The Catch Weight option is checked and also set to 40 kilograms. The Purchase Cost is the price per kilogram, for example, if the user buys a salmon that is exactly 40 kilograms, the total cost will be 40 x £4.07 = £162.80.

Fig.1 – Catch Weight Product Master

Creating a Purchase Order

Fig.2 shows a Purchase Order with both a catch weight salmon and a non-catch weight salmon. In both instances, an order is placed in ‘Quantity’, where the user is purchasing one product each where each is 40 kilograms. The price for the catch weight product is shown as cost per kilogram, whilst the non-catch weight product is the cost of each.

Please note: When ordering a catch weight item, the quantity figure will display as purple to signify that the product is a catch weight item.

Fig.2 – Purchase Order with Non / catch weight products

Posting at Receiving

The difference between the two products is shown at the Receiving Center. The catch weight product has the ‘Receiving Unit’ in weight, whilst the non-catch weight item is as ‘EACH’, as shown in Fig.3.

Fig.3 - Non / catch weight products at Receiving Center

The advantage of catch weight can be seen in Fig.4. It is simple for the user to amend the catch weight salmon to the correct weight – which in turn will correct the ‘Received Cost’.

Correcting the non-catch weight salmon would mean the user would have to determine the new weight as a percentage of the original weight. This method is more time consuming, prone to errors, and less accurate as the ‘Quantity’ is limited to 2 decimal places.

Fig.4 – Amending Non / catch weight products at Receiving Center

Comments

Please sign in to leave a comment.