Overview

It may be necessary for a limited time to prevent certain functions, or users accessing certain areas of a Site during a temporary close.

This article is designed to support the temporary closure of Sites, and how to manage the Site during that time.

Preventing Orders from being Sent from a Site

Settings can be applied to prevent Orders from being sent from a Site to all Suppliers.

To do so:

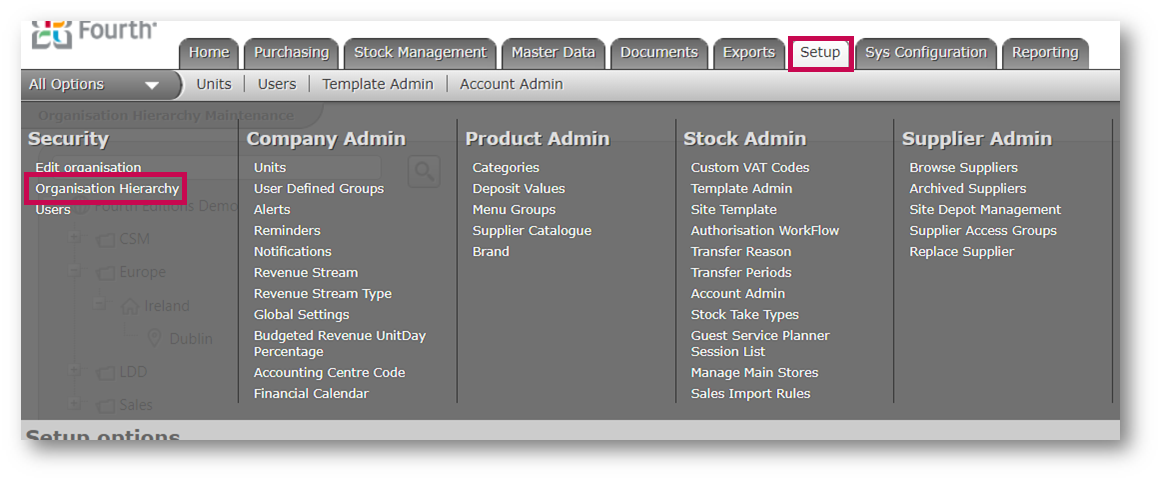

- Within the Setup tab, select All Options

- Select Organisation Hierarchy

Fig.1 – Organisation Hierarchy

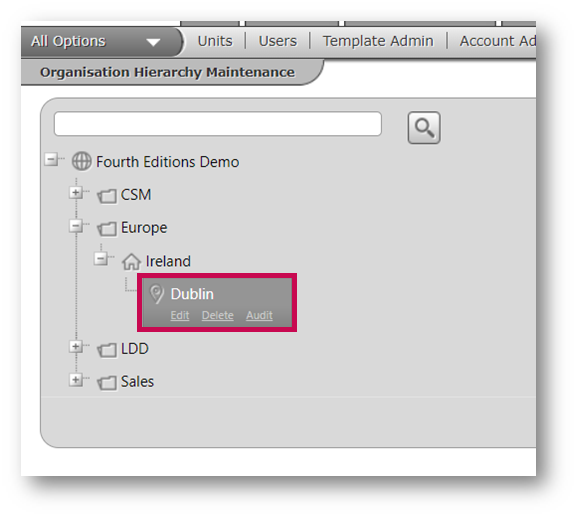

- Expand the hierarchy using the + icons until the lowest level (Sites) is displayed

Fig.2 – Site Level

- Select Edit

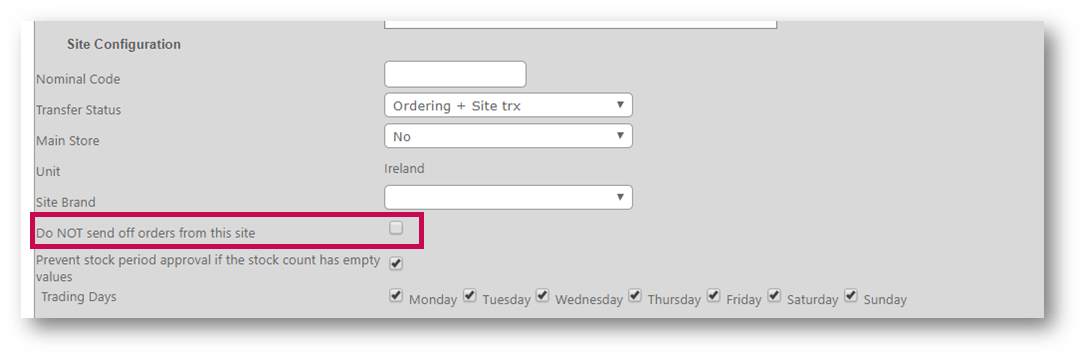

- A pop-up window will display, scroll down to the Site Configuration section

- Tick the Do NOT send off orders from this site box

- Save

Fig.3 - Do NOT Send Off Orders from this Site Setting

Fig.3 - Do NOT Send Off Orders from this Site Setting

Please Note: Sites will still be able to place orders within the system, and they will display in the Pending tab within Stock Management. However, the orders will not be transmitted to Suppliers with the above setting applied.

Preventing Orders from being Sent to Specified Suppliers

It is possible to prevent Sites from being able to place an order with specific Suppliers.

To do so:

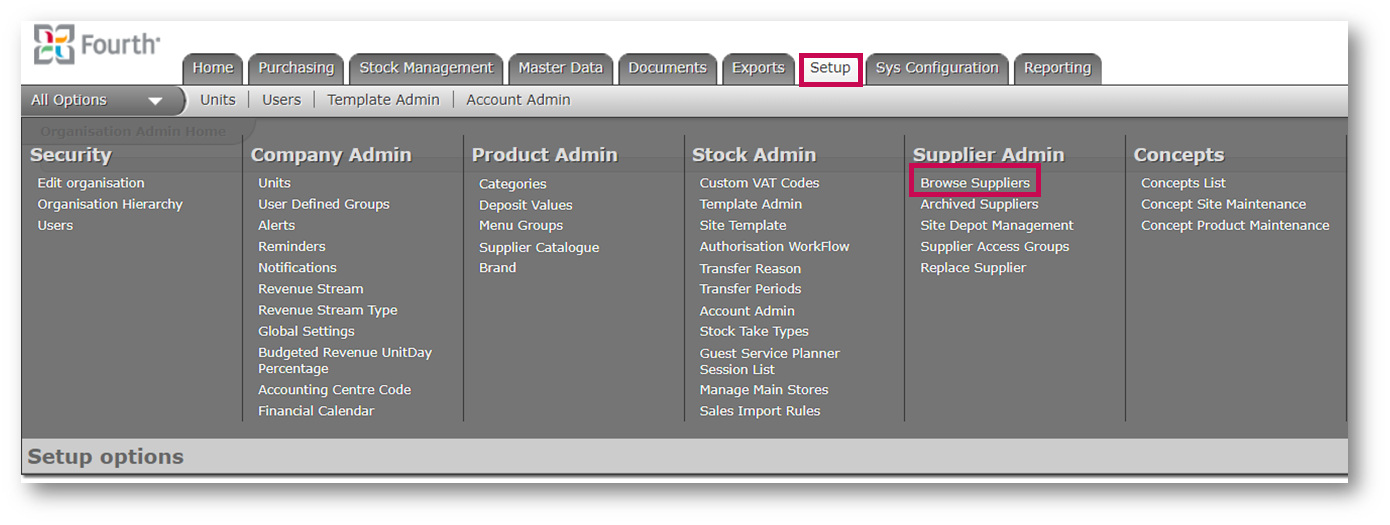

- Go to the Setup tab and select All Options

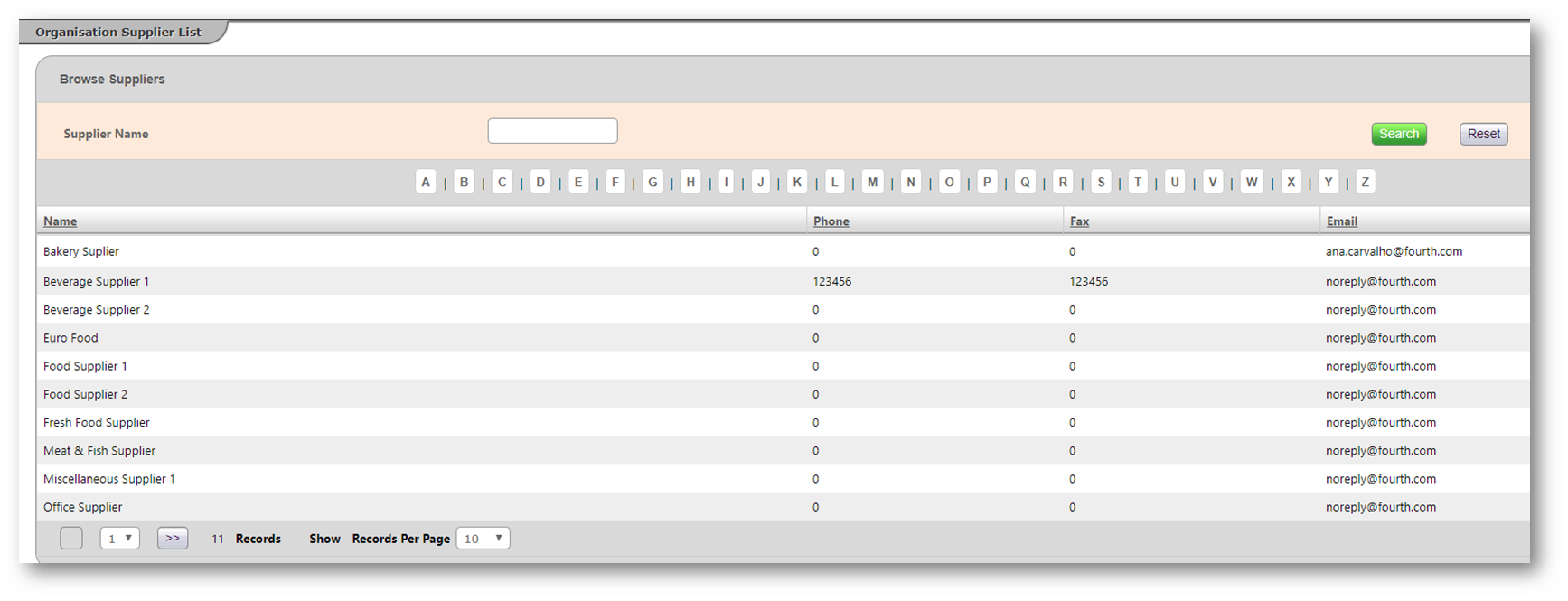

- Select Browse Suppliers

Fig.4 – Browse Suppliers

Fig.4 – Browse Suppliers

This will return a list of all the Suppliers assigned within the Organisation.

- Select the Supplier from the list which is to be prevented from ordering

Fig.5 – Supplier List

Fig.5 – Supplier List

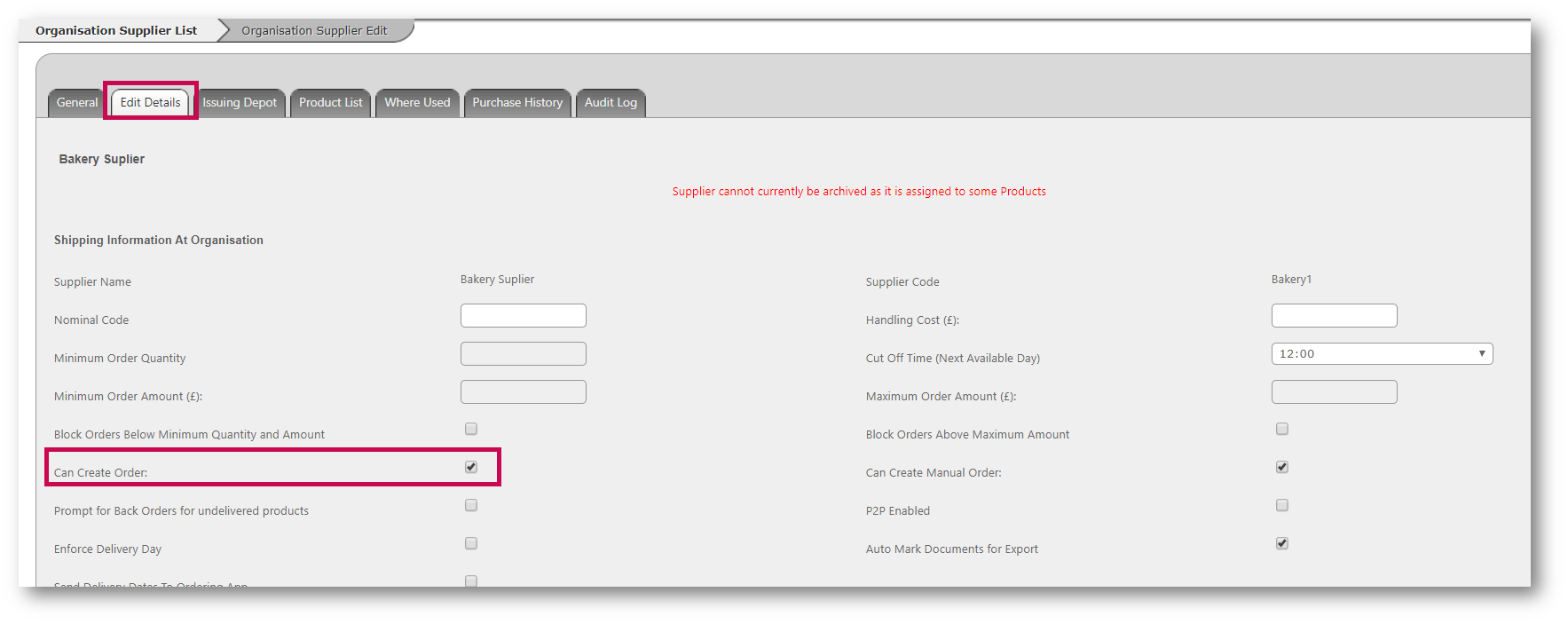

- Within the Supplier details, go to the Edit Details tab

- Un-tick the Can Create Order box

- Save

This will prevent the Supplier from displaying in the drop-down list when a user creates an Order by Supplier from the Purchasing tab within Inventory.

Fig.6 – Can Create Order Setting

Fig.6 – Can Create Order Setting

Stock Period Administration

Amending Stock Period Dates

If the Stock Period for a Site needs to be amended, the Stock Period End Date can be adjusted within Stock Period Maintenance.

To do so:

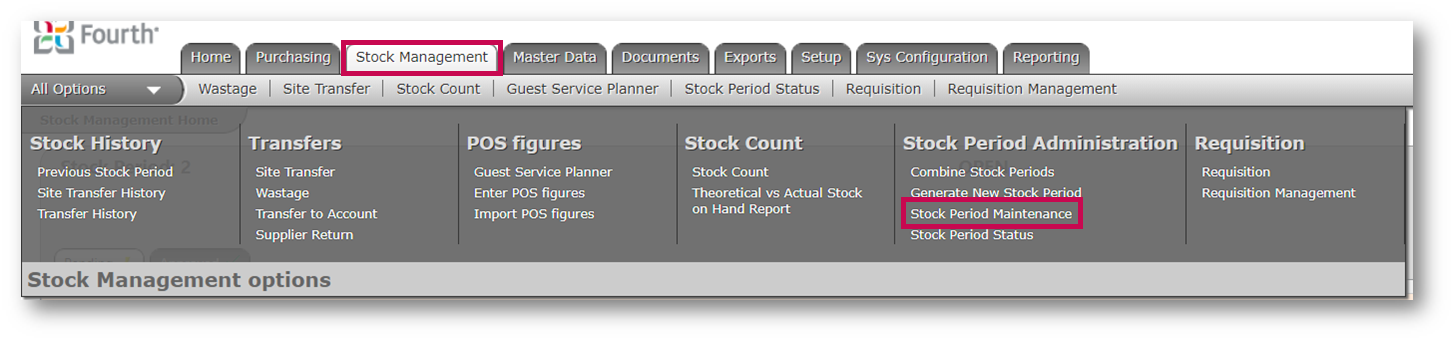

- Go to the Stock Management tab and select All Options

- Select Stock Period Maintenance

Fig.7 – Stock Period Maintenance

Fig.7 – Stock Period Maintenance

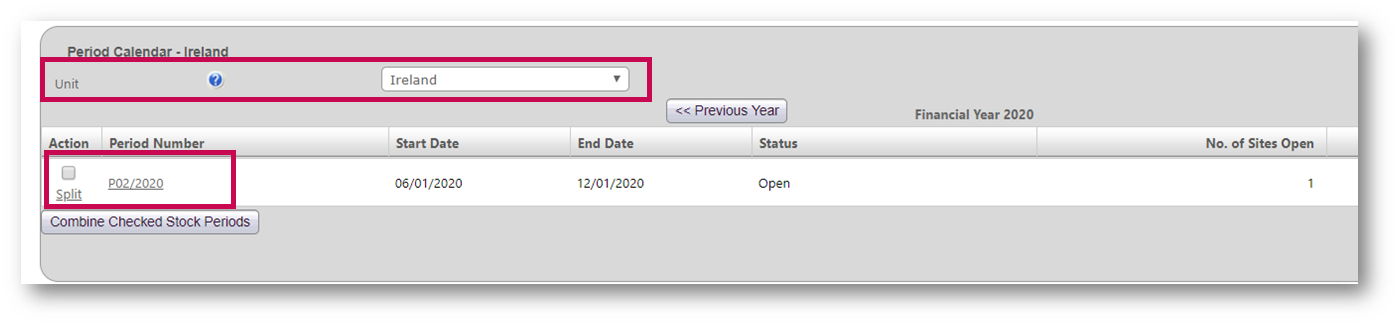

- From the Stock Period Maintenance screen, select the required Unit from the drop-down menu, and then select the current Stock Period

Fig.8 – Stock Period and Unit Selection

Fig.8 – Stock Period and Unit Selection

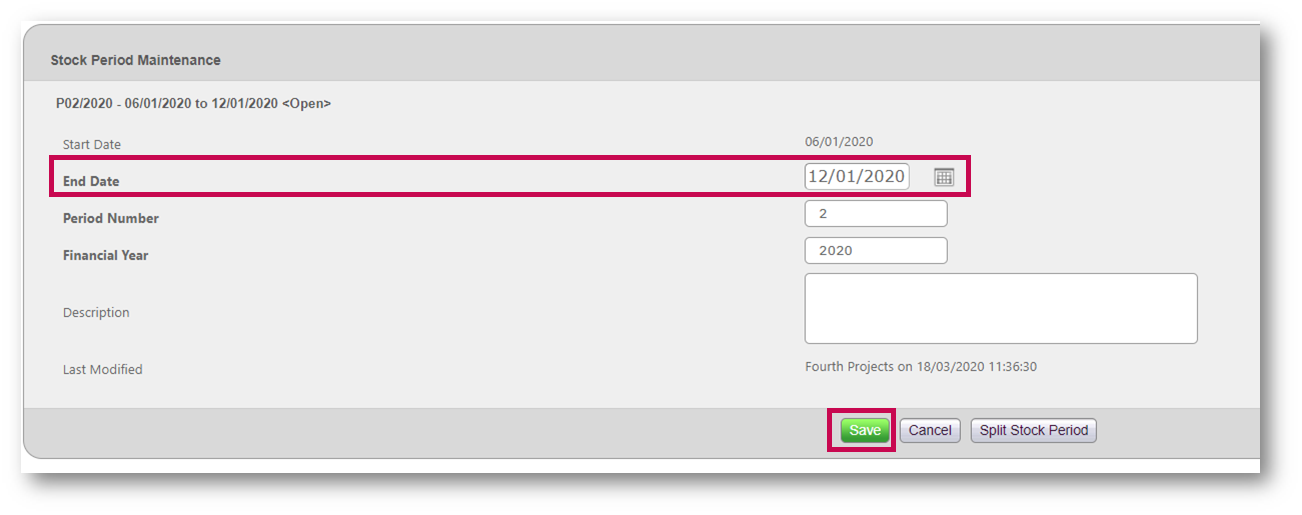

- Within the current Stock Period, the End Date of the period can be adjusted

- Set the new date and Save

Please Note: If there are multiple Stock Locations (Sites) within a Unit, this date change will apply to all.

Fig.9 – Editing Stock Period End Date

Fig.9 – Editing Stock Period End Date

Generating a New Stock Period

Inventory automatically generates a new Stock Period when a site approves their Stock Period. This new period automatically defaults to the Stock Period length which has been configured against each Site e.g. 7 days, Monthly, 4/4/5.

To create a Stock period which is set for a bespoke length:

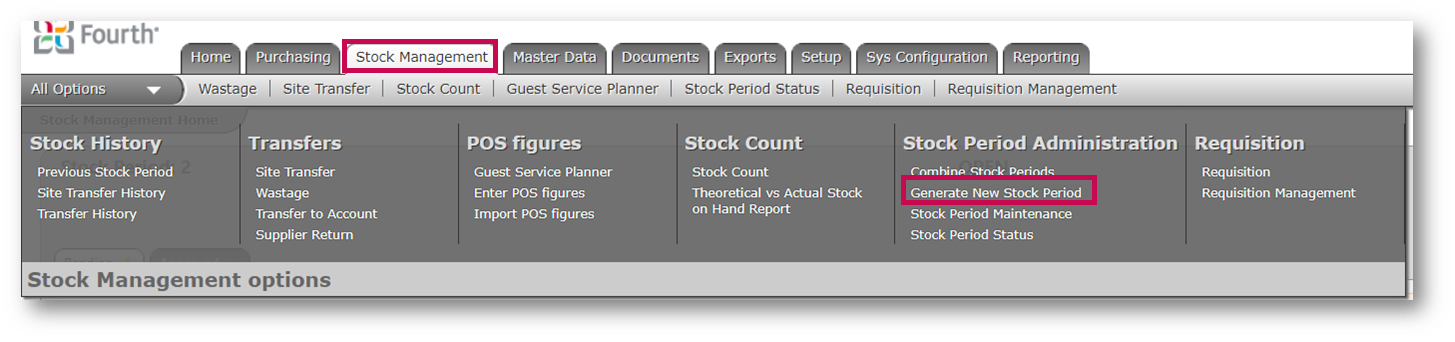

- Within the Stock Management tab, select All Options and then Generate New Stock Period

Fig.10 – Generate New Stock Period

Fig.10 – Generate New Stock Period

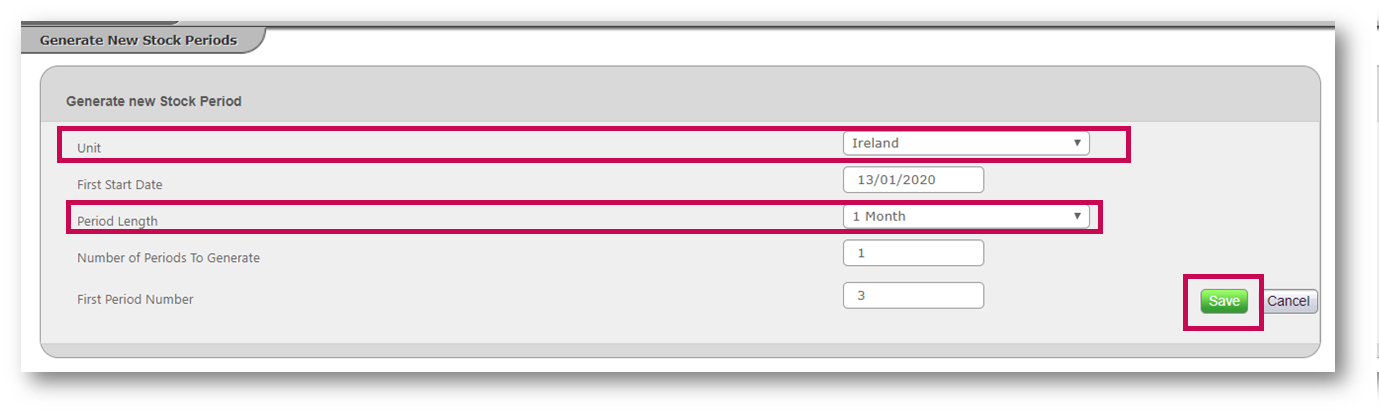

- Select the Unit from the first drop-down menu

The Period start date will be auto-populated based on the closing date of the previous Stock Period created for that Unit.

- Select the Period Length which is to be applied to the new Stock Period

These are pre-set lengths, however, once applied they can be amended using the Amending Stock Period Dates section above.

- Save

Fig.11 – Unit and Period Length Selection

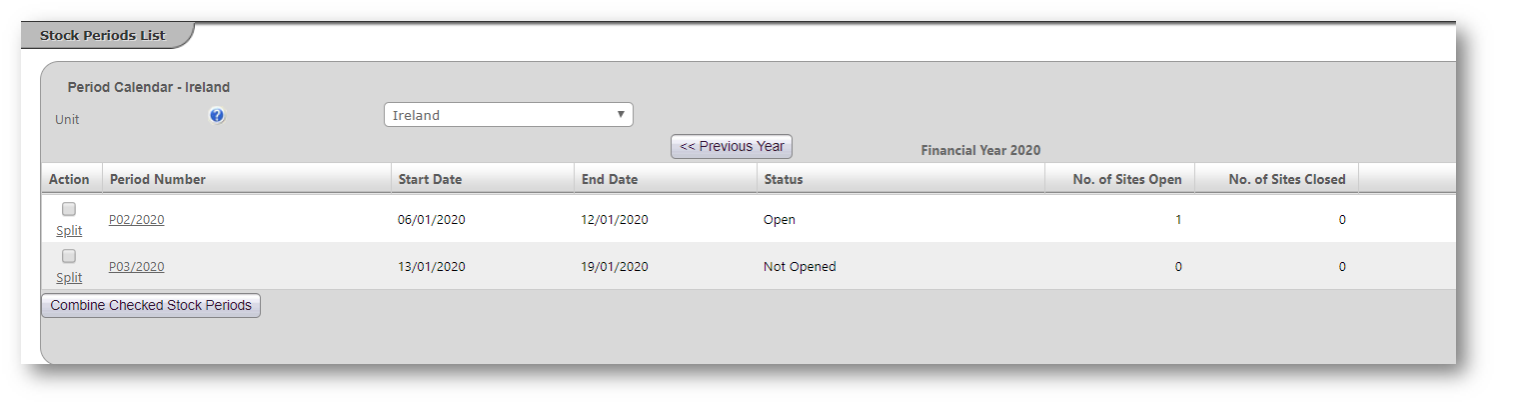

The new Stock Period can be seen within the Stock Period Maintenance tab, and upon approval of the current period, it will automatically roll into the newly created period.

Fig.12 – New Stock Period

Fig.12 – New Stock Period

Managing Stock Counts

Setting Counts to Zero

Within Inventory, it is possible to apply a zero count to Products by Category.

To do so:

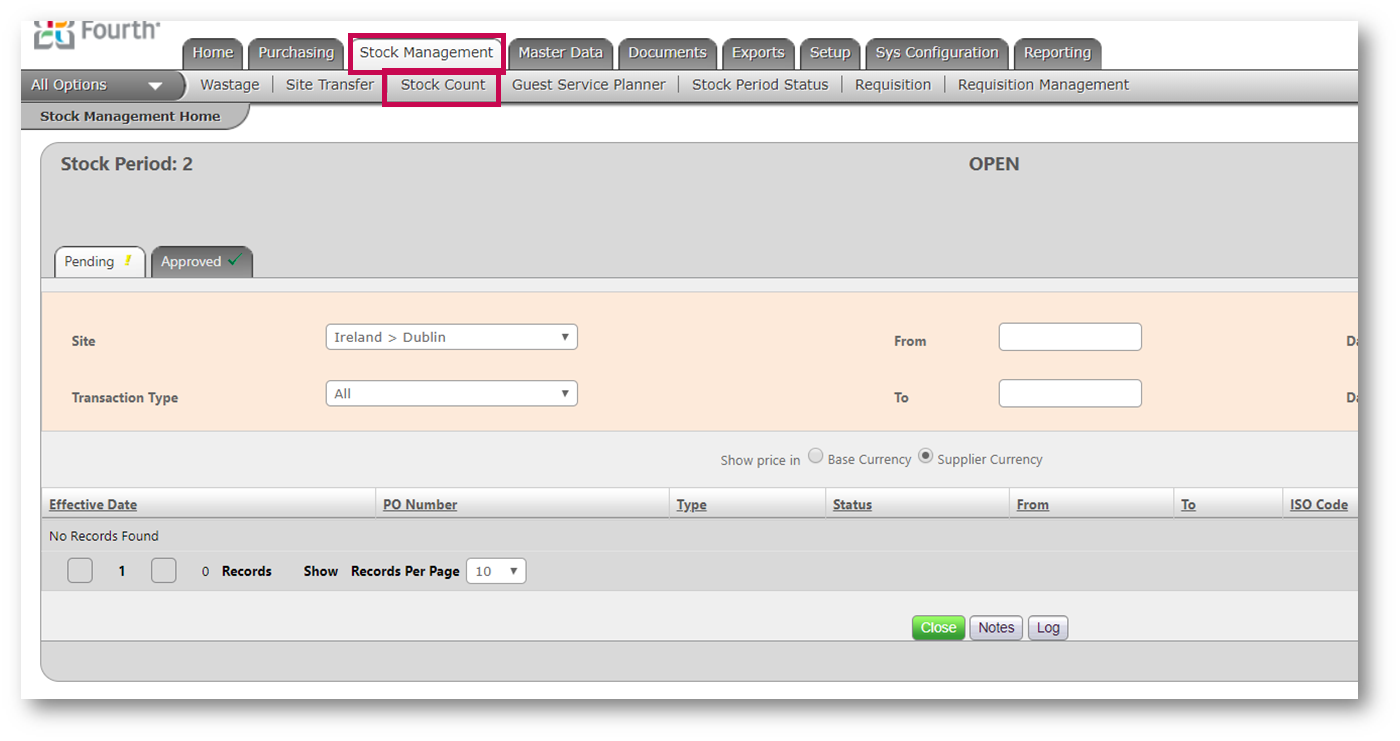

- Select the Stock Management tab and then Stock Count

Fig.13 – Stock Count in Stock Management

Fig.13 – Stock Count in Stock Management

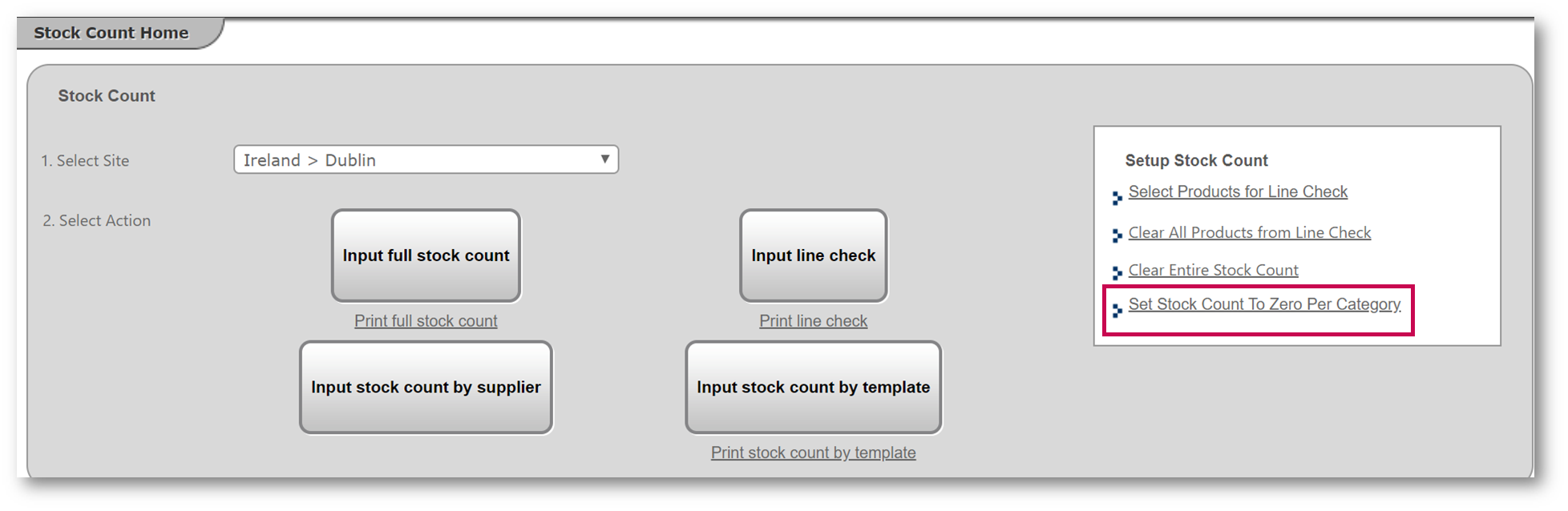

- Select Set Stock Count To Zero Per Category

Fig.14 – Set Stock Count to Zero Per Category

Fig.14 – Set Stock Count to Zero Per Category

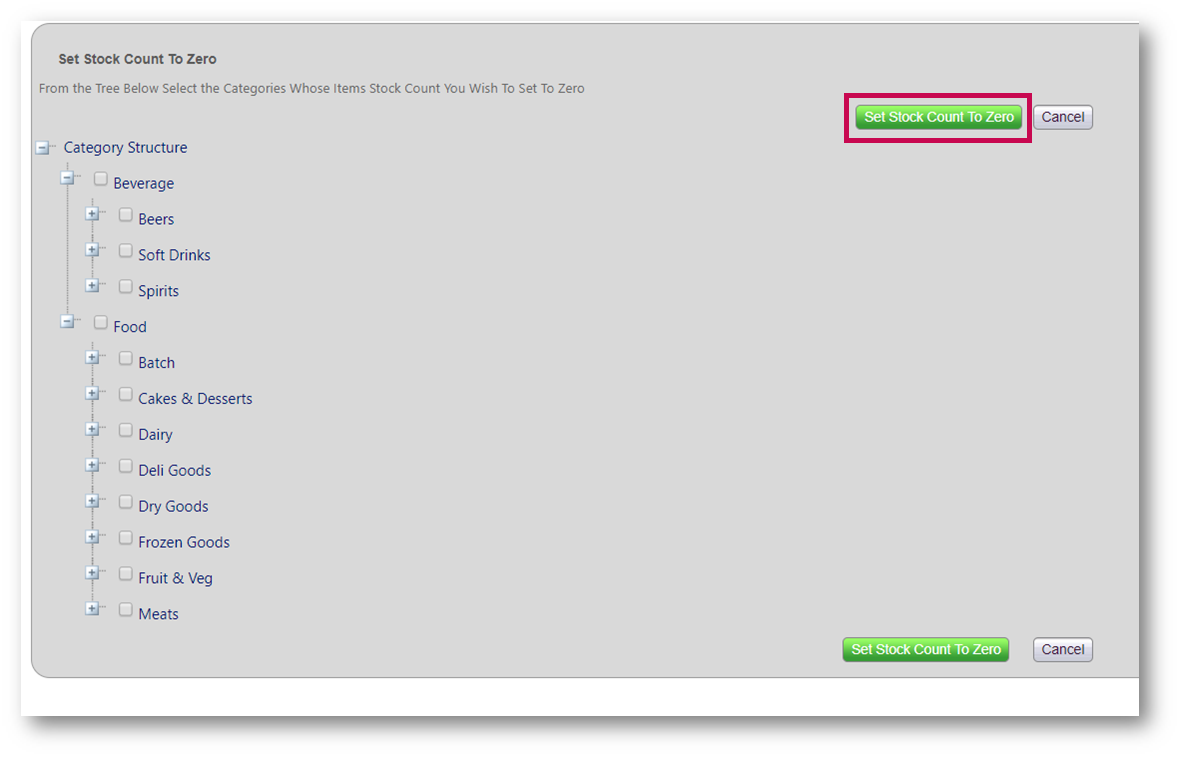

- Use the + icons to expand the Categories out

- Select the top level box to automatically check the boxes for each Category below it

- Select the required Categories of Products which require a zero count to be applied to

- Select Set Stock Count to Zero

Fig.15 – Set Stock Count to Zero

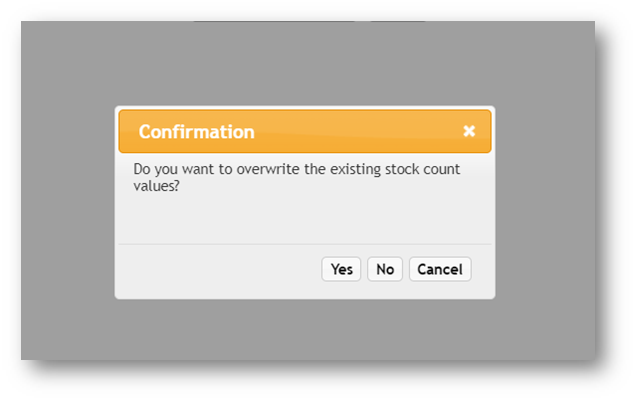

A pop-up warning will display to advise that any existing count values will be overwritten.

- To proceed, select Yes

- To re-select categories, select Cancel

Fig.16 – Confirmation Pop-Up

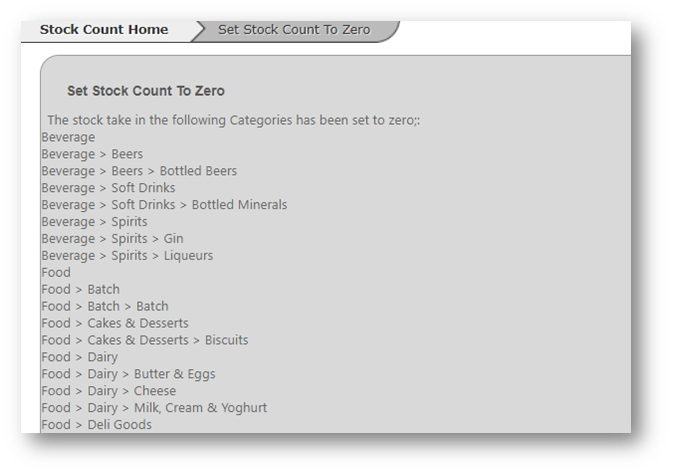

If Yes is selected, a summary will display of the Categories which have had the zero count applied to them.

Fig.17 – Summary of Categories with Zero Count Applied

Fig.17 – Summary of Categories with Zero Count Applied

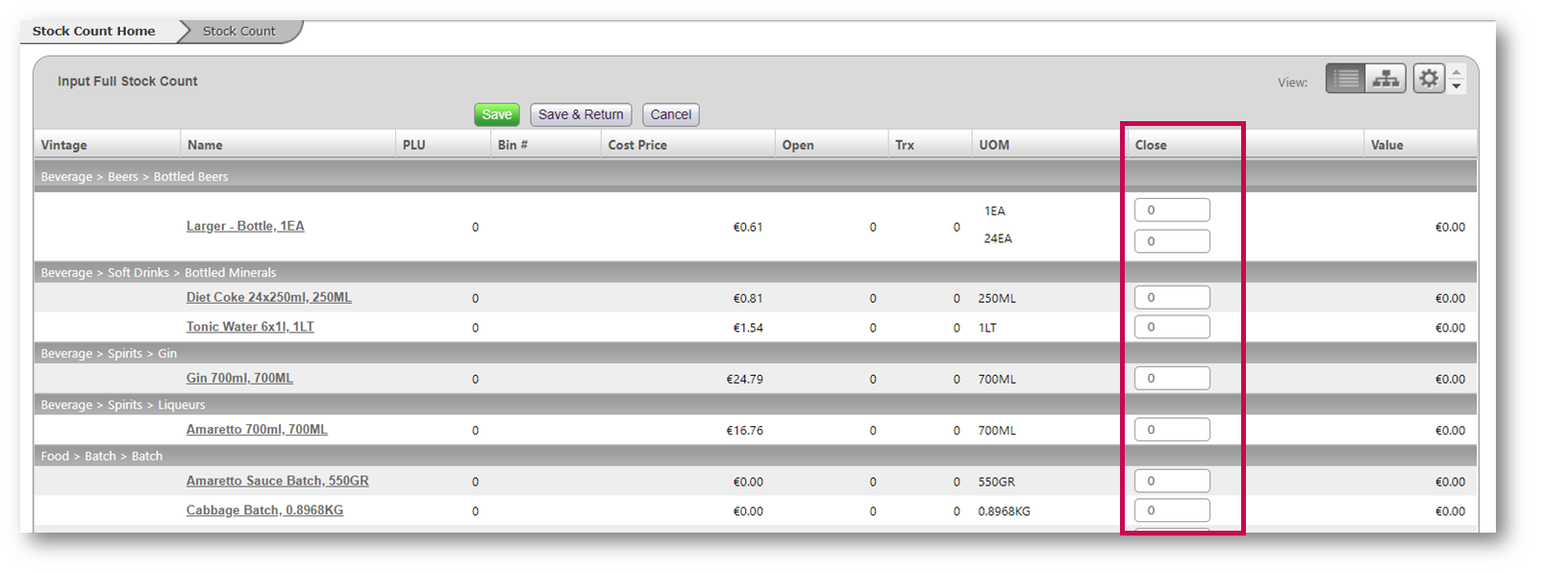

Within the Stock Count entry screen, zero will be applied to all Products within the chosen Categories.  Fig.18 – Close Quantity Column

Fig.18 – Close Quantity Column

If the zero count has been applied in error, an actual count can still be entered:

- Enter the actual count into the Close quantity field to overwrite the zero figure

The Stock Period can then be approved as normal with a closing stock value and quantity of zero.

Generating a Theoretical Closing Count

Within Inventory, it is possible for the system to generate a Theoretical Closing Quantity and Value. Where no counts have been entered against a Product, Inventory will generate a theoretical stock count resulting in no variances against the Products.

This can be used if there is no requirement for a Site to enter a Stock Count for a period in order to move the Site into their next Stock Period.

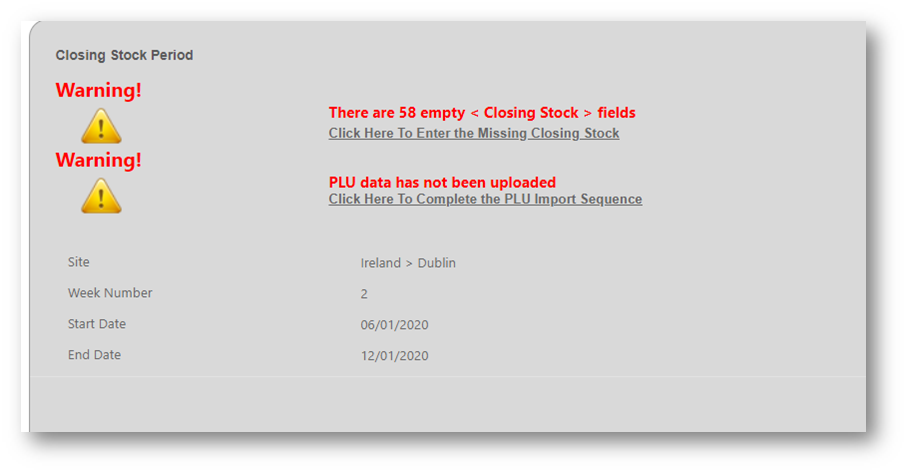

When closing the Stock Period, a pop-up will display to warn that there are empty closing stock values. The period can still be closed despite this warning.

Fig.19 – Warning Message

Fig.19 – Warning Message

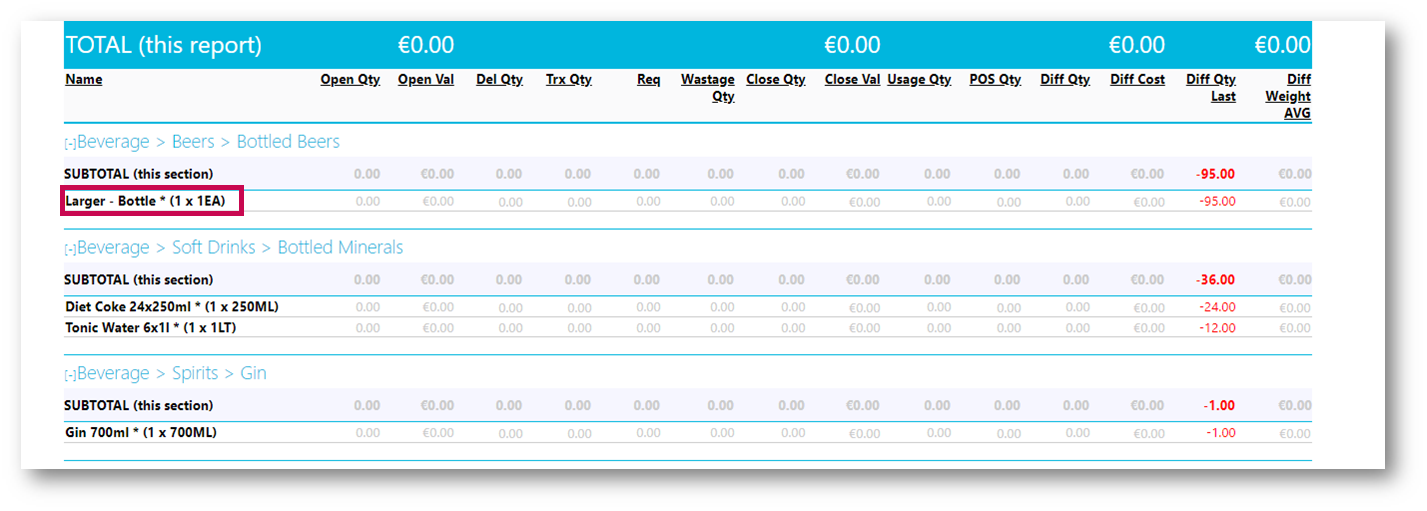

When running the Stock Reconciliation report, a * will display next to the Products denoting that no count has been entered against the Product, and the system has calculated the Closing Quantity Value.

Fig.20 - * Icon

Fig.20 - * Icon

The Stock Period can then be approved. There may be Global Settings applied which prevent the approval of a Stock Period with no values entered. If the Approve button is greyed out, please contact Fourth to have the setting updated.

Please Note: If there are products within RME (Recipe and Menu Engineering - formerly known as 'Starchef') that have been set to populate with a 0 count, this will need to be de-selected against each ingredient within RME and updated to stock using the FnB actions. This will update Inventory and ensure that a close and theoretical can be generated, as above.

Temporary Site Closure - Video Overview

Comments

Please sign in to leave a comment.