Overview

When an ingredient is created in Recipe & Menu (formerly known as StarChef) there are multiple different data points that can be entered against the ingredient. The fields to display and that which are mandatory, are configured according to each customer's requirements. There are a number of fields that are compulsory for an ingredient to be published to Fourth’s Inventory solution.

This article will outline the fields that are required for Inventory and any special considerations to bear in mind when populating data in these fields.

Ingredient Fields Relevant to Stock

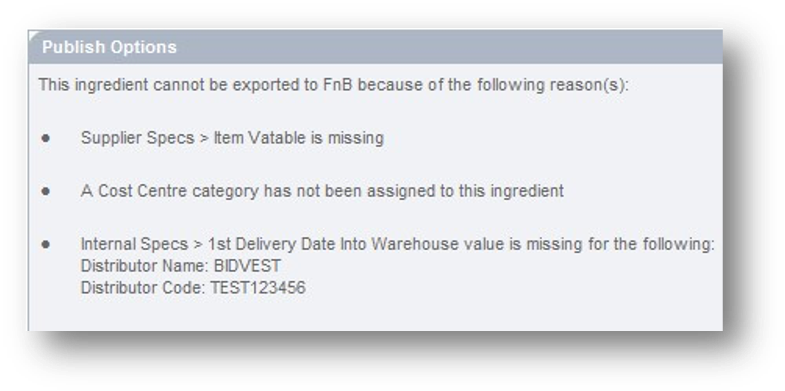

Key stock-related ingredient fields must be completed so an ingredient can be published to Fourth’s Inventory solution (formerly known as FnB Manager). These fields are mandatory and Recipe & Menu will generate a warning if any of the key fields are missed when ‘Publish to FnB’ is selected.

Fig 1 – Publish to FnB button

Below in Table 1 is a list of the mandatory inventory fields within Recipe & Menu. If any relevant Inventory fields are missing from the ingredient, a message will appear when the ‘Publish to FnB’ link is selected.

Fig 2 – Warning if mandatory fields are missing

Fig 2 – Warning if mandatory fields are missing

Table 1 – Mandatory Inventory Ingredient fields:

|

StarChef Tab |

Field Name |

Notes, including Stock (Inventory) Function |

|

Details |

Ingredient Name |

This is the field that will be sent to stock for ordering and stock counting. In the stock system, the ‘Ingredient’ is referred to as a ‘Product’. |

|

Details |

Ingredient Cost Model |

Relates to Alternate Ingredients. This is only relevant for cost models within Recipe & Menu. It is not necessarily the ingredient cost model in the stock system. |

|

Details |

Exclude from GP |

If ticked the product will be excluded from the overall stock GP. This would be applicable to products such as consumables. |

|

Details |

Zero Stock Count |

Should this ingredient always display ‘0’ in an ingredient line for every stock count? |

|

Details |

Bin Number |

Optional stock value: Additional Information > Bin Number |

|

Details |

Is Adjustment Item |

Allows a product to be created to adjust the total cost of a transaction. Can be hidden in Recipe & Menu once an adjustment item has been created for each supplier (as needed). |

|

Details |

Transfer/Requisition Status |

Controls if sites can transfer the product internally. |

|

Supply Details |

Supplier Name |

Must exactly match Supplier Name in the Stock system. (This is a managed service for inventory customers). |

|

Supply Details |

Supplier (product) Code |

Supplier (product) code will facilitate EDI ordering & invoice matching. |

|

Supply Details |

Cost Price |

Price of pack size (see next row). |

|

Supply Details |

Supply Quantity & UOM |

Pack size for ordering. 3 mandatory fields: number, number, and unit of measure. 1 optional field: pack description. Last two mandatory values (number, unit of measure) also create a stock counting unit in the stock system. See below for additional stock counting unit (unit size). Please note: Once the 4th value ‘pack description’ is sent to the stock system, it cannot be changed. Also, the pack description does not appear on the purchasing page (in the stock system) but rather on the stock count tally sheet. |

|

Supply Details |

Unit Size & UOM |

Defines the stock counting unit of the product. 2 mandatory fields: number, unit of measure. 1 optional field: unit size description. Please note: UoM must be same as Supply Quantity UoM. Please note: If only one stock counting unit is desired, unit size mandatory values must be the same as the last two mandatory Supply Quantity values (number, UoM). |

|

Supply Details |

Alternative Issuing Unit 1 |

Optional: This value does appear on the stock count sheet and on the stock transfer sheet. |

|

Supply Details |

Alternative Issuing Unit 2 |

Optional: This value does appear on the stock count sheet and on the stock transfer sheet. |

|

Supply Details |

Split Package Size |

Optional: Creates a case size in the stock system. For example, if a product’s supply quantity (pack size value) is 12 x 750 ml and Split Package Size = 6, the user can order either a case of 12 (bottles) or 6 (bottles). |

|

Supply Details |

Wastage |

Always take into account when ingredient data goes to the stock system. The best practice is to only populate if ingredient wastage is relevant all the time. |

|

Supplier Spec |

Item Vatable |

Three possible values: Y = 20%, N = 0%, – (dash) = exempt. |

|

Supplier Spec |

Country of Origin |

Optional: Country of origin |

|

Supplier Spec |

Vintage |

Optional: Vintage |

|

Internal Spec |

1st Delivery to Warehouse |

Controls product availability/unavailability once the product is assigned to site. If the field is populated with a date in the future the product will be unavailable to order/transfer until the specified date is reached. If the product needs to be made temporarily unavailable to order, this date can again be set into the future. This will have an immediate effect if the ingredient is 'updated to stock'. |

|

Alternates |

Create Alternate Ingredient |

This tab allows additional supplier/pack size relationships to be added to a master product thus ensuring that the product appears only once on the stock sheet. The master ingredient is, by default, specified as the ‘preferred supplier’. This is only relevant for theoretical recipe cost within Recipe & Menu. Please note: Nutritional data is sourced from the master ingredient reference. |

|

Categories |

Assign Cost Centre category |

Categories are created in the Admin tab. Cost Centre categories are for Ingredients and Batch Recipes. Menu Group categories are for Standard Recipes. The Cost Centre and Menu Group categories have implications throughout the stock system i.e. positioning on order/stock sheet, cost centre reporting. |

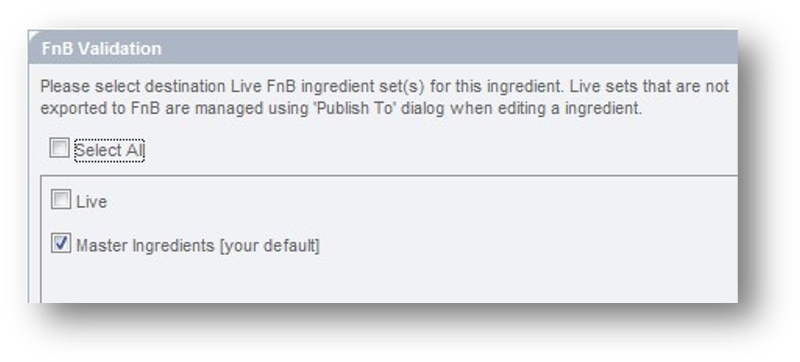

- If all information is populated correctly, the option will be given to publish to the relevant StarChef live set according to the sets configured within an organisation

Fig 3 – Live set options

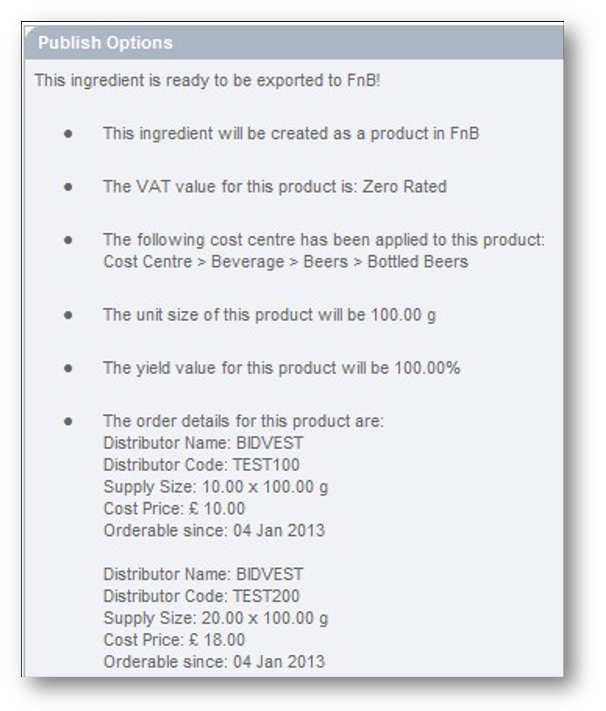

Once a live set is selected, the ingredient is ready to be exported to Inventory. A summary of the ingredient information will be displayed for verification.

Fig 4 – Information that will be published

- To sync with Inventory, select next

The organisational structure and the relevant sites to publish to will be displayed.

- Select the appropriate sites and select next to complete the process

Recipe Fields Relevant to Stock

There are also key stock-related recipe fields that must be completed so that a recipe, whether it be a batch or standard recipe, can be published to Fourth’s Inventory solution. These fields are not mandatory in Recipe & Menu but are required for correct reconciliation of ingredients within recipes at the end of the inventory period.

Batch Recipes

Table 2 – Mandatory Batch Recipe fields

|

Tab |

Key Fields |

Notes |

|

Details |

Recipe Name |

Appears on Stock Count sheet |

|

Details |

Product type |

|

|

Details |

Stock Count Type |

Relevant to stock taking: Count by size/Count by serving. Count by size, stock count size = Yield > Cooked Weight value (number, UoM) Count by serving, stock count size = Yield > Portion Size (# servings, ‘servings’) Please Note: When 'count by serving' is used any UOM can be entered (i.e. each or serving) however this will be shown in inventory as 'portion' (PTN). |

|

Yield |

Cooked Weight, Quantity and UoM |

Required both for stock and nutrition functions. The Cooked Weight UoM family, e.g. weight or volume, cannot be altered once the Batch Recipe has been published to Inventory (FnB). The Cooked Weight is a required field in order to correctly account for the volume of ingredient used within each recipe. |

|

Yield |

Portion Size UoM |

Portion size must be ‘numeric value x ‘each’ UOM’. Typically ‘# of servings x 'serving’ is advised to avoid confusion. |

|

Categories |

Cost Centre category |

A pop-up will appear.

|

Standard Recipes

Table 3 – Mandatory Standard Recipe fields

|

Tab |

Key Fields |

Notes |

|

Details |

Product type |

Defaults to ‘Standard'. |

|

Ingredients |

Servings |

Please note: Should always be written as a recipe for 1 serving |

|

Yield |

Cooked Weight, Quantity and UoM |

Required both for stock and nutrition functions. The cooked weight will be used to reconcile the value of ingredients within Inventory if a recipe is used as a sub-recipe or a batch. If 1 serving of a sub-recipe is added to a standard recipe the cooked weight will be used to identify what the actual volume & % of the recipe should be accounted for in the main recipe. The Cooked weight is a required field in order to correctly account for the volume of ingredient used within each recipe. |

|

Yield |

Portion Size UoM |

Portion size must be numeric value x each UOM. Typically # of servings x - 'serving’ is advised to avoid confusion. |

|

Categories |

Menu Group category |

A pop-up will appear.

|

Comments

Please sign in to leave a comment.