Overview

Applying ingredient-level wastage in Recipe & Menu Engineering (RME) enables automated accurate recipe costing and nutrition calculations where an ingredient has a fixed wastage percentage.

A good example of this is a tin of olives in brine. Whilst the brine counts towards the overall weight of the product, it is not actually utilised in recipe builds, and is treated as wastage.

It is recommended that ingredient-level wastage is applied to ingredients that have a clear definition of useable product. Fruit & vegetables that require peeling, for example, are open to different interpretations of wastage amount as well as seasonal fluctuations.

![]() Please note: If not using Fourth's 'Inventory' product, please refer to RME: Ingredient Level Wastage, which is very similar to this article but has some important differences.

Please note: If not using Fourth's 'Inventory' product, please refer to RME: Ingredient Level Wastage, which is very similar to this article but has some important differences.

Application

Throughout this article, a tin of olives will be used as an example, and has the following properties:

Product Name: Mixed Olives in Brine

Supplied Quantity: 1 x 2kg tin

Drained (useable) Weight: 1.5kg

Wastage: 25% (500g brine)

Cost: £20

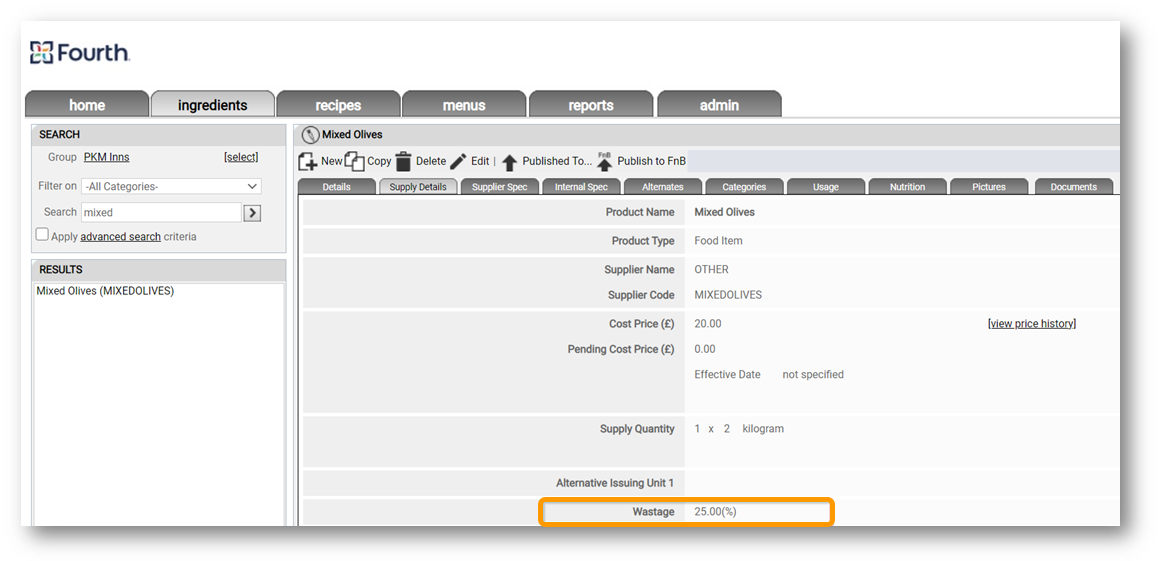

Ingredient Setup

Within RME, Wastage can be applied against an Ingredient from the Supply Details tab:

Fig.1 - Wastage applied

Fig.1 - Wastage applied

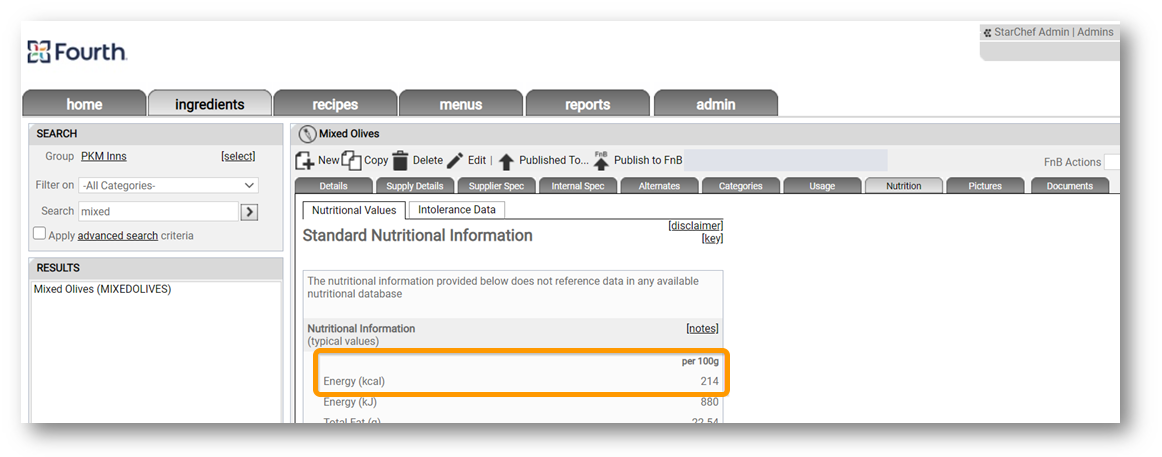

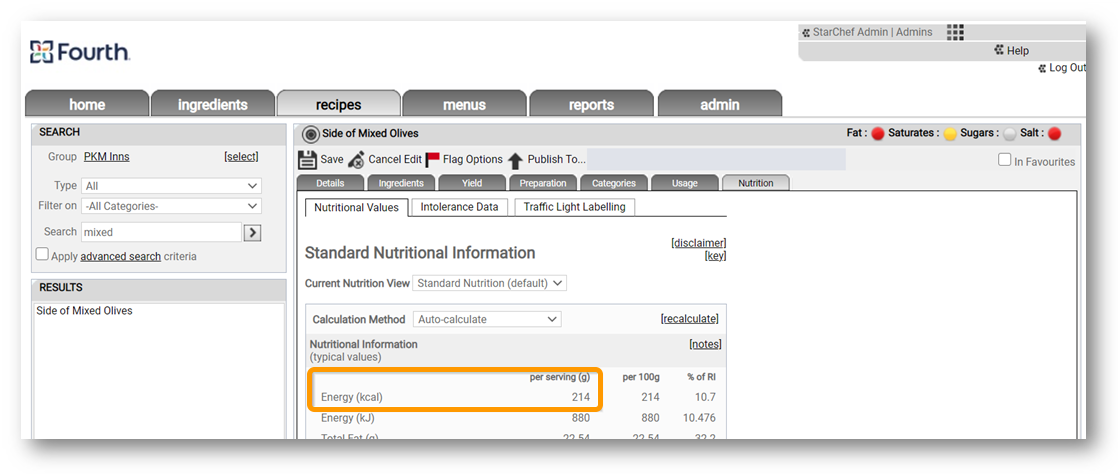

There is a nutritional value of 214kcal per 100g:

Fig.2 - Nutritional value

Fig.2 - Nutritional value

Recipe Build

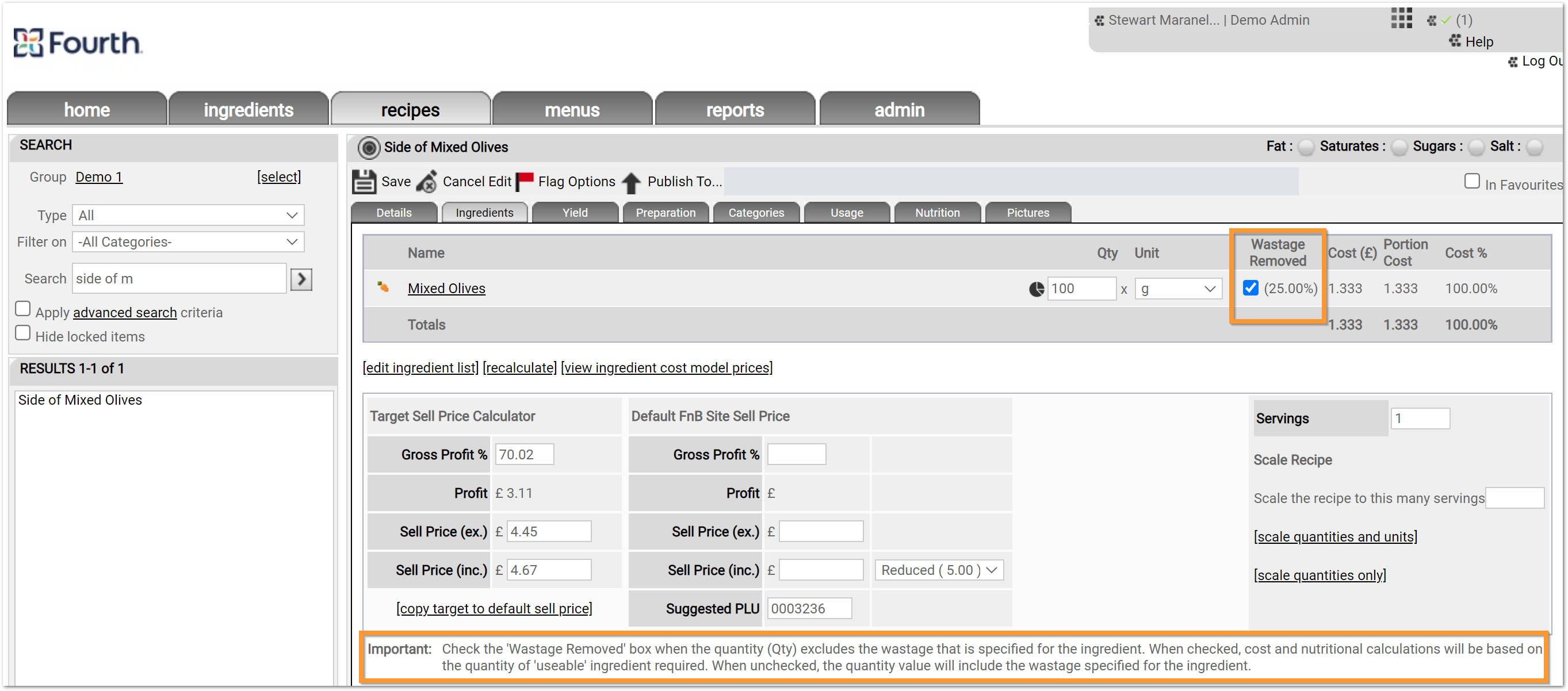

RME will default to calculate all recipes based on the wastage having been removed from the recipe quantity.

Therefore, any quantities added to a recipe must be the usable quantity.

This can be de-selected on a recipe ingredient basis if required.

Example – 100g of Olives

The recipe quantity is 100g of drained olives.

RME calculates the recipe calculations based on the brine having been drained. This can be seen by the green tick against the Wastage Removed column (the wastage is removed from the entered recipe quantity).

- RME costs the recipe in the following way:

- 2kg (2000g) – 25% wastage = 1.5kg (1500g)

- £20 / 1.5kg (1500g) = 1g:1.33p

- 100g * 1.3p = £1.33

Fig.3 - Wastage removed

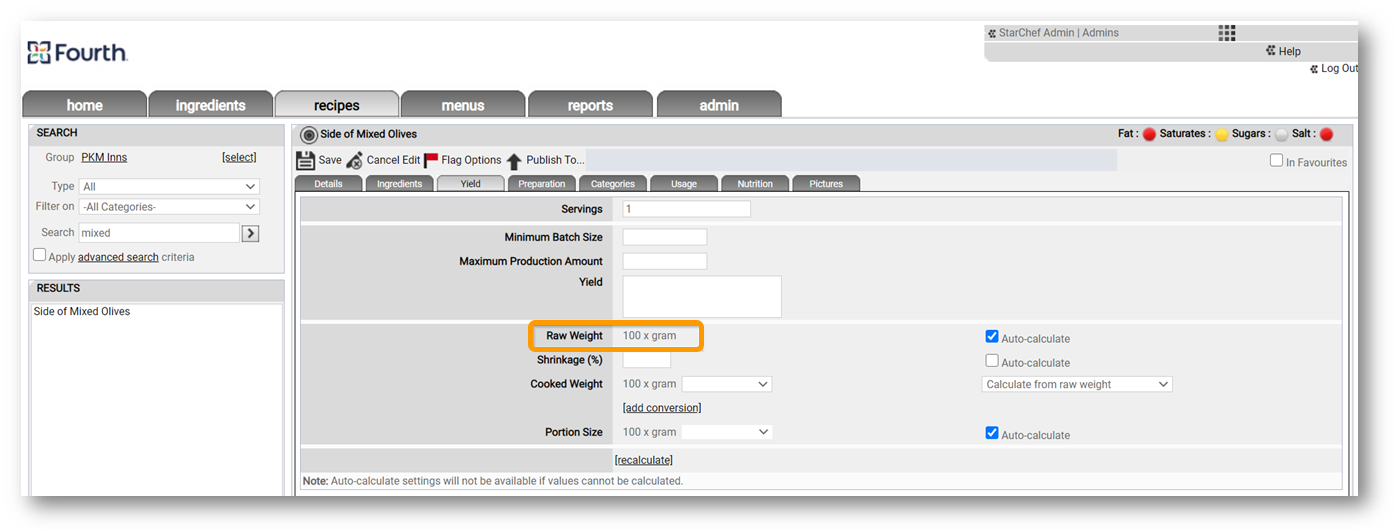

- As the wastage has already been removed, the Yield tab shows the full 100g of useable product:

Fig.4 - Full 100g of usable product

Fig.4 - Full 100g of usable product

Nutrition values are calculated based on the 100g of useable quantity in the recipe:

Fig.5 - Nutrition values

Fig.5 - Nutrition values

Inventory Recipe Costing

Inventory will apply the same costing logic when costing a recipe containing ingredients with ingredient-level wastage. Depending on the specific configuration, the cost seen by sites may differ from those seen in RME due to associated supplier and ranking combinations.

Inventory Theoretical Stock Depletion/Usage

Inventory will apply the same wastage logic when calculating theoretical stock depletion for sales received from Point of Sale.

Example:

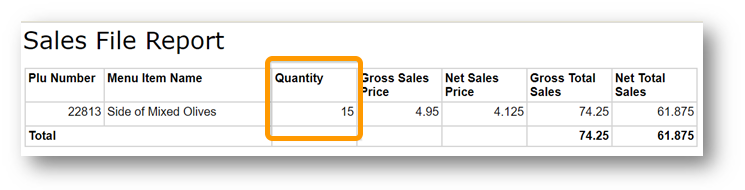

- 15 portions of 100g (wastage removed) sold

- 100g portion + 25% wastage = 133.33g (rounded)

- 15 x 133.33g (rounded) = 2kg (2000g)

Therefore for 15 portions sold, the theoretical consumption is 1 full 2kg unit

This can be seen in the below results:

- Sold Quantity: 15 portions

Fig.6 - Quantity in Sales File Report

Fig.6 - Quantity in Sales File Report

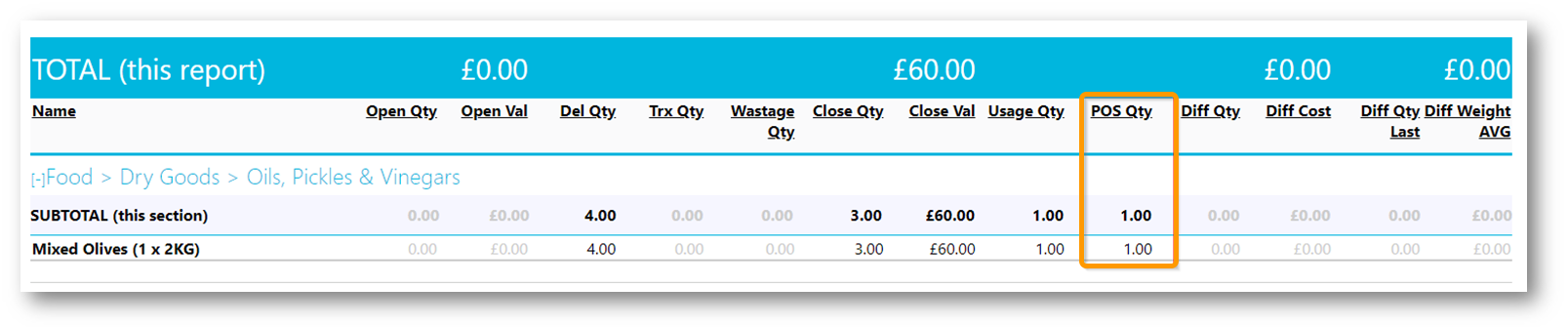

- Opening Quantity: 0

- Delivered Quantity: 4 units (4 x 2kg = 8kg)

- Closing Quantity: 3 units (£60)

- Actual Usage: 1 unit

- POS Quantity: 1 unit (2kg/2000g) - based on 15 portions sold

- Difference: 0

Fig.7 - POS Quantities

Fig.7 - POS Quantities

![]() Remember: the quantity entered in a recipe will be after (excluding) wastage percentage identified in Ingredient setup as default.

Remember: the quantity entered in a recipe will be after (excluding) wastage percentage identified in Ingredient setup as default.

Comments

Please sign in to leave a comment.