What are Modifiers?

Modifiers are used in EPOS configuration when an item (button) selected requires additional information or requires additional stock items to be used. There are many different uses of modifiers:

- Additional modifiers – to add products to the original recipe i.e. ‘with cheese’ on a burger or ‘with coke’ when selecting a shot of vodka.

- Adjustment modifiers – to remove an original recipe item but add an alternative i.e. ‘no ham, mushroom instead’

- ‘Meal Deal’ modifiers – where the main item selected generates the revenue and no cost, and all other modifiers have the recipe cost associated.

- Modifiers with no PLU – typically descriptive modifiers, but no

- Descriptive modifiers – add information to the item selected these modifiers typically have no PLU assigned as they are used to send operational messages to different areas of the business i.e. cooking of steak i.e. medium –well.

Each type of modifier is configured in a slightly different way, although the important element is the cost and quantity of the stock used when a modifier is selected.

Typically modifiers will have their own individual PLU reference, and are therefore treated very much like standard menu items. In a small number of cases modifiers are not assigned a PLU reference, information on how to deal with items of this configuration can be found in the relevant section.

How are Modifiers Configured on FnB?

Modifiers are typically set up as standard menu items as they have their own unique PLU reference. They are created in exactly the same way as a normal menu item would be created.

Modifiers where an ingredient is added to the original item…

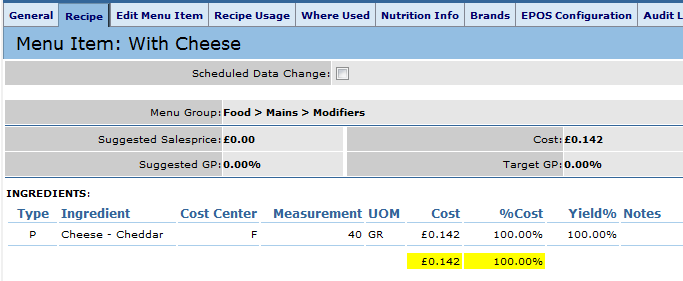

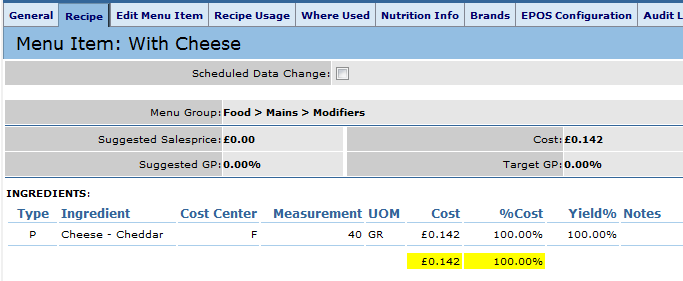

When a modifier is used to add ingredients to the original recipe it is treated very much like an independent menu item. Examples of modifiers that are configured in this way is ‘with cheese’ or ‘lemonade splash’ when a burger or shot of vodka is selected. The item is not charged for, as all of the revenue is generated on the main PLU, however the stock needs to be accounted for and therefore a recipe needs to be created.

The menu item should be created, linked to the appropriate PLU and the relevant ingredients added – there is no requirement to add a sales price, only the cost of the stock items used needs to be attributed.

Create a standard a recipe and add the additional ingredients only

Modifiers where the original item is changed in some way…

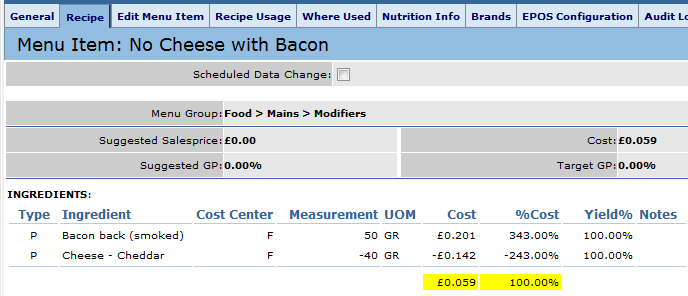

It is also possible to use modifiers to change the original recipe by removing an existing ingredient and replacing this item with a substitute; this would be applicable if a modifier is used to remove cheese & add bacon to a recipe as this is a common substitution.

To create this modifier a standard menu item should be created and the relevant items added as normal, however a negative quantity can be entered against an ingredient to transfer this back into stock after it was deducted from the main recipe.

In this example the main burger recipe would contain ‘cheese’ and the modifier is changing the original recipe in some way rather than adding an additional ingredient. It is also possible to simply use modifier to remove a main recipe ingredient by just recording the ‘cheese’ in the menu item in the below example.

Modifiers where the original item is changed in some way…

It is also possible to use modifiers to change the original recipe by removing an existing ingredient and replacing this item with a substitute; this would be applicable if a modifier is used to remove cheese & add bacon to a recipe as this is a common substitution.

To create this modifier a standard menu item should be created and the relevant items added as normal, however a negative quantity can be entered against an ingredient to transfer this back into stock after it was deducted from the main recipe.

In this example the main burger recipe would contain ‘cheese’ and the modifier is changing the original recipe in some way rather than adding an additional ingredient. It is also possible to simply use modifier to remove a main recipe ingredient by just recording the ‘cheese’ in the menu item in the below example.

This set up is only currently possible in live FnB; StarChef, and therefore R9, is not capable at adding a negative ingredient to a recipe. This is part of the road map, although will be dealt with after the work internationalisation.

Modifiers where the main item is a revenue item with no cost – ‘Meal Deals’…

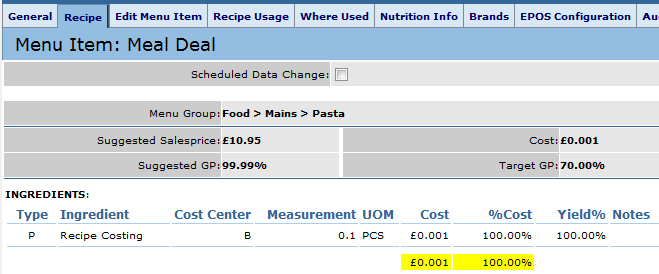

For items such as ‘meal deals’ the main PLU has no cost associated but attributes all of the revenue where the modifiers have no revenue associated but contributes all of the cost. In this instance the modifiers are set up as per the ‘additional item modifiers’ above, however the main PLU must have a cost associated in order to reconcile the sales.

1. Create a ‘recipe costing’ product which can be used to associate a ‘fake’ cost to the recipe.

a. The product should be set up a 1 x 1ea with a cost of £0.01

2. This is then added to a recipe – 0.1 pcs can be added which will provide a total cost of £0.001

a. FnB recognizes cost to 3DP adding an item in this way is the smallest amount that can be added and recognized. This will also ensure that only a small amount is added to the theoretical COS as for every 100 sold, only 1p will be added.

Modifiers with no PLU attached…

If modifiers have no PLU’s attached there is no way to reconcile the stock in FnB, a modifier must have a PLU attached in order to associate stock. Typically these types of modifiers are only used to send messages such as ‘with ice’, however if a customer does have a modifier that uses stock set up in this way they should be made aware that the stock will not be used when the modifier is selected.

What are Batch Items?

Batches are sub-recipes that are made by a business (either on site or at a secondary location) and are required to be stock counted at the end of the period.

When should a batch item be produced on site?

If a batch is made in a stock location then it should be produced on site at that location, for example if a business makes their own pizza dough the kitchen will have finished dough balls available to count at the end of the stock period, but they also have the raw ingredients such as flour or yeast. When the batch is counted at the kitchen the batch should be reconciled back to raw ingredients as the kitchen orders and stock counts these ingredients as well.

A batch should not be produced on site if the site where the batch is assigned wants to treat this batch as a product rather than a recipe; if the site does not require information on the raw ingredients within the batch as they do not stock these items. A good example would be olives that are marinated on site by the kitchen and sold at the bar, the batch is assigned to both the Kitchen & Bar although the produced on site status is different at each location.

At the Kitchen – The raw ingredients are ordered, used and stock counted; the recipe for the finished marinated batch is transferred to the bar. The transfer of the batch traces back to the ingredients to provide variances for the ingredients on the stock reconciliation.

At the Bar – no raw ingredients are stock counted, or ordered; the batch is treated very much as if it is a product purchased from a supplier, but in this instance the supplier is the kitchen within the same restaurant. The batch is not produced on site, so appears as a product in its own right on the stock reconciliation at the bar. None of the ingredients within the batch are required to be assigned to the bar, as the batch is treated like a product.

Comments

Please sign in to leave a comment.