What's Changing?

In RME alternates can now be defined with units of measure (UOM) outside of the UOM family of the base ingredient - if a conversion between UOM’s has been applied at the base ingredient level. This information is interfaced from RME to Inventory to support the use of these alternates relative to the parent stock item.

Please note: Alternates with purchase-item specific conversions for the same ingredient are not supported.

Release date: 6th April 2021

Reason for the Change

Previously, without this capability, customers were required to create duplicate ingredients (i.e. create new parent ingredients rather than add alternates) which in turn required the creation of duplicate recipes and/or other difficult workarounds.

Customers Affected

The functionality is available to all RME/Inventory customers.

Release Notes

The following release notes focus on the impact in Inventory and connected apps where alternates are specified in a different UOM family to the base ingredient. Please also see:

- RME Release Note - April 2021: Natasha's Law

- RME Release Note - April 2021: Alternate Ingredient Pack Size, Updated Import API

- RME Release Note - April 2021: Nutrients with '0' Value, 'Suitable For' Intolerance Values Aggregation

RME

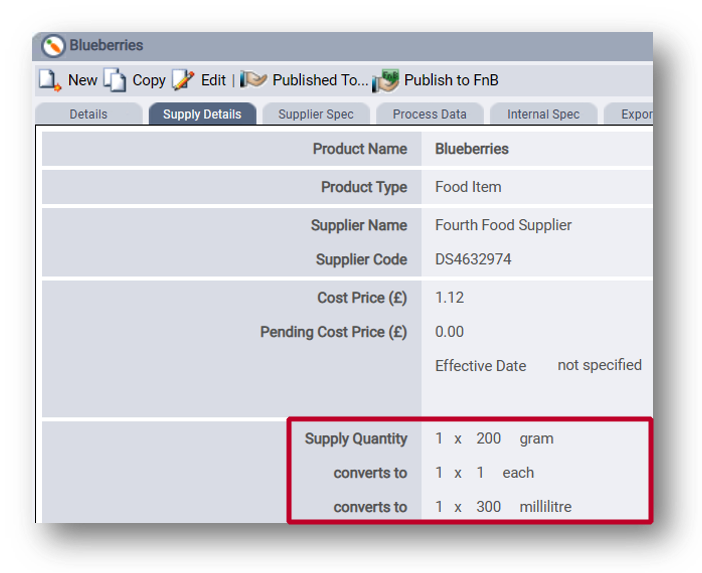

Where an ingredient exists in RME with a conversion from supply quantity to another UOM type (see Fig.1), in the example below “Blueberries” with a conversion of 1 x 200 gram = 1 x 1 each, alternates can now be created with a different UOM family (see Fig.2).

Fig.1 - Parent ingredient base UOM conversion

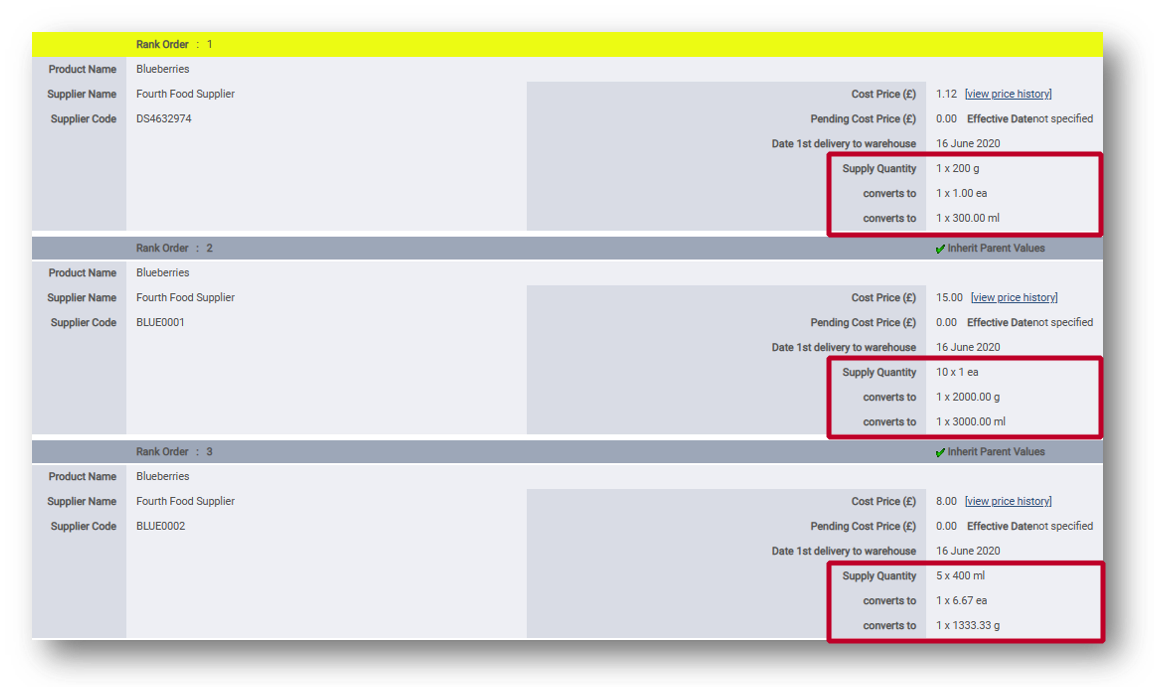

The conversion between the UOM’s is represented against each alternate.

Fig.2 - Alternate to parent conversion

Master Data

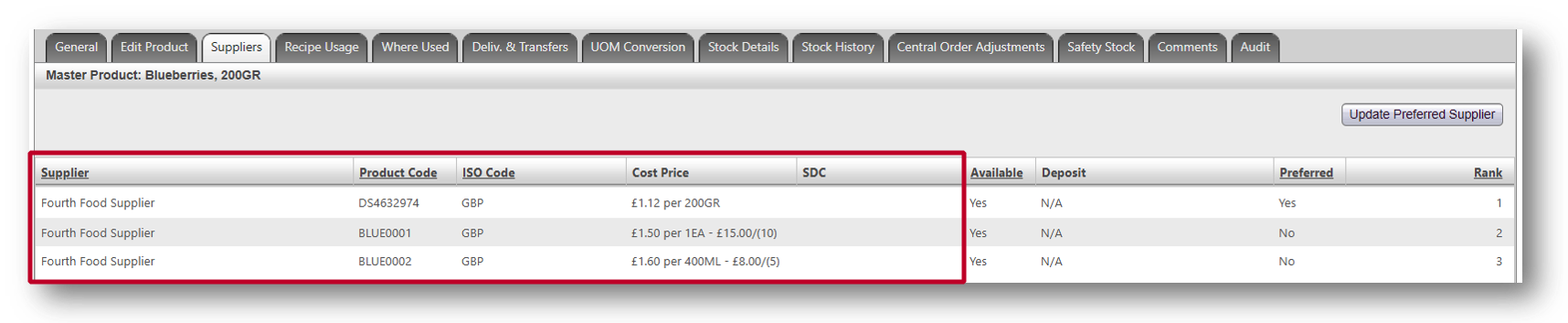

When the ingredient is successfully synchronised to Inventory all alternates as configured in RME, different UOM families or otherwise should be visible against the product in Inventory, Master Data > Product > Suppliers (see Fig.3).

Fig.3 - Alternates in different UOM families in Inventory

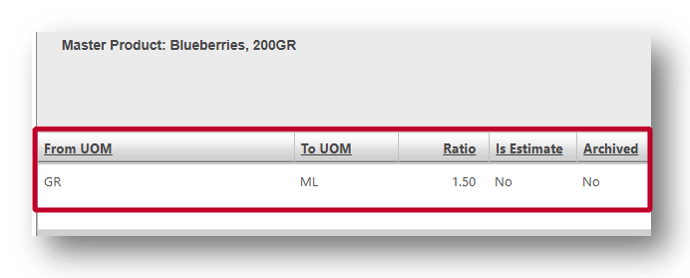

Conversion from the base UOM, relative to the conversion specified in RME is stored against the stock item within Inventory. The conversion stored can be seen through Master Data > Product > UOM Conversion (seen Fig.4).

In the below example 1 GR is the equivalent of 300 / 200 = 1.50 ML.

Fig.4 - Parent UOM conversion in Inventory

Purchasing

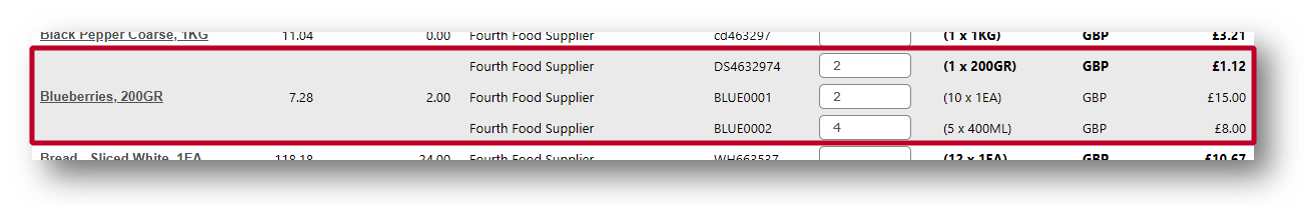

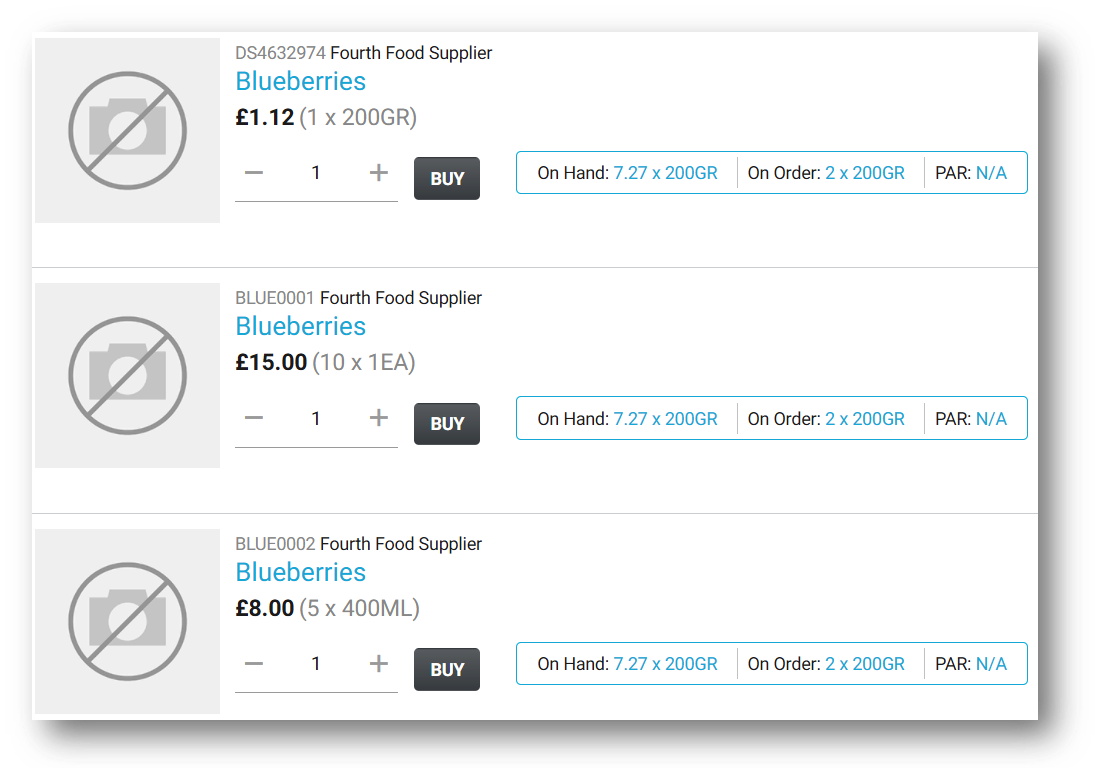

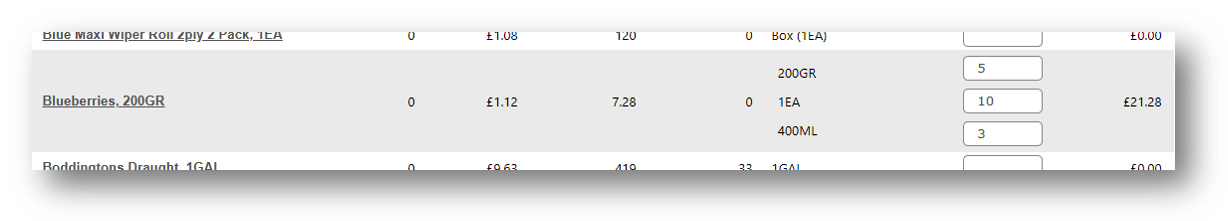

Once the product has been synchronised to Inventory, provided a site has access to the product and supplier(s) of the product, it will be visible in the configurations defined in both core Inventory Purchasing (Fig.5) and the Ordering app (Fig.6).

Fig.5 - Alternates in different UOM families when Purchasing in Inventory

Fig.6 - Alternates in different UOM families in the Ordering app

On order and on hand values are represented in the base UOM for the product, i.e. multiples of 200GR.

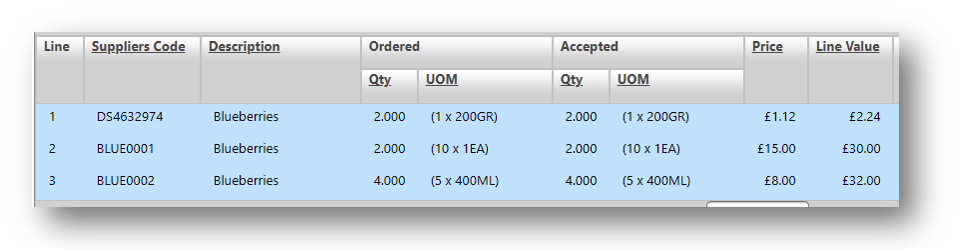

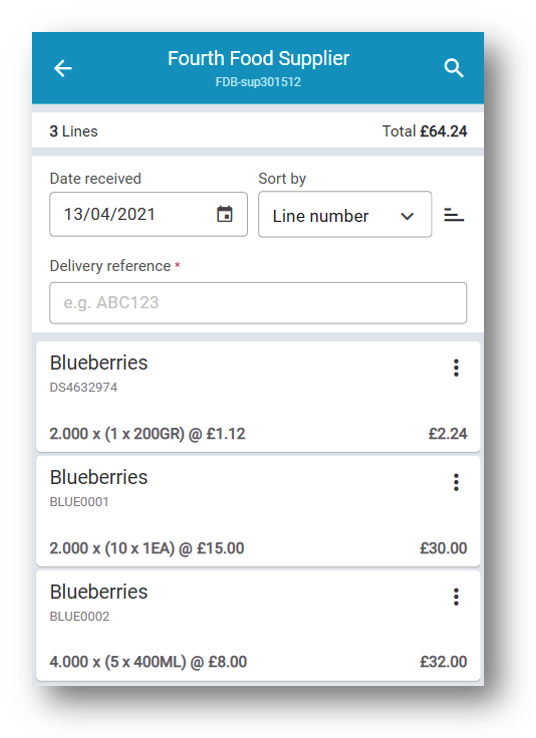

Receiving

The products can then be received in the respective sizes that have been set in Inventory (Fig.7) and the Receiving app (Fig.8). On receipt, the update to Inventory will be relative to the base UOM, in this example 200GR.

Fig.7 - Receiving in different UOM families in Inventory

Fig.8 - Receiving in different UOM families in the Receiving app

Counting

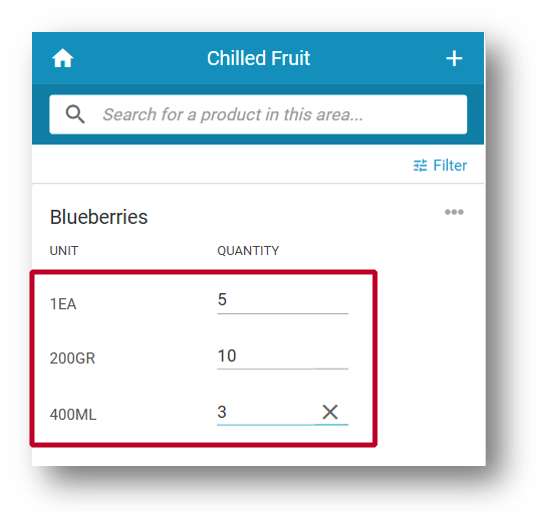

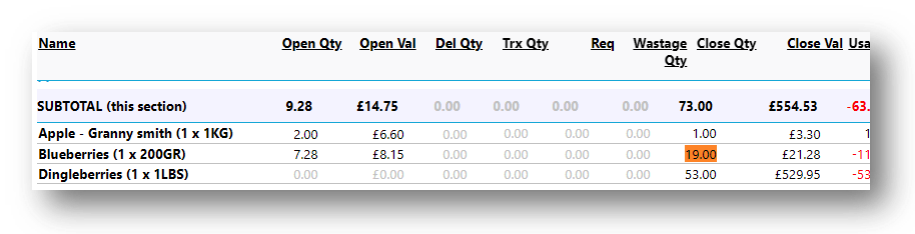

The products can then be counted in the respective sizes that have been set in the Counting app (Fig.9) and Inventory (Fig.10). On update of the count quantity will be captured relative to the base UOM, in this example 200GR.

Fig.9 - Counting in different UOM families in the Counting app

Fig.10 - Stock count in different UOM families in Inventory

In the above example, the closing count quantity represented in the base UOM, 200GR – this is calculated as:

- 5 x 200GR

- 10 x 1EA = 10 x 200GR

- 3 x 400ML = 3 x (400ML x 1.5) = 4 x 200GR

Therefore, a total of 19 x 200GR – this is reflected in reporting, e.g. Stock Reconciliation (see Fig.11).

Fig.11 - Closing quantity reflected in base UOM, where counts recorded in other UOM families

Comments

Please sign in to leave a comment.